Technical Commentary

Technical Information Related to Dicing

We introduce useful technical information about the dicing process.

We explain the dicing processing methods and types,

the causes of defects such as chipping, and countermeasures.

About Dicing

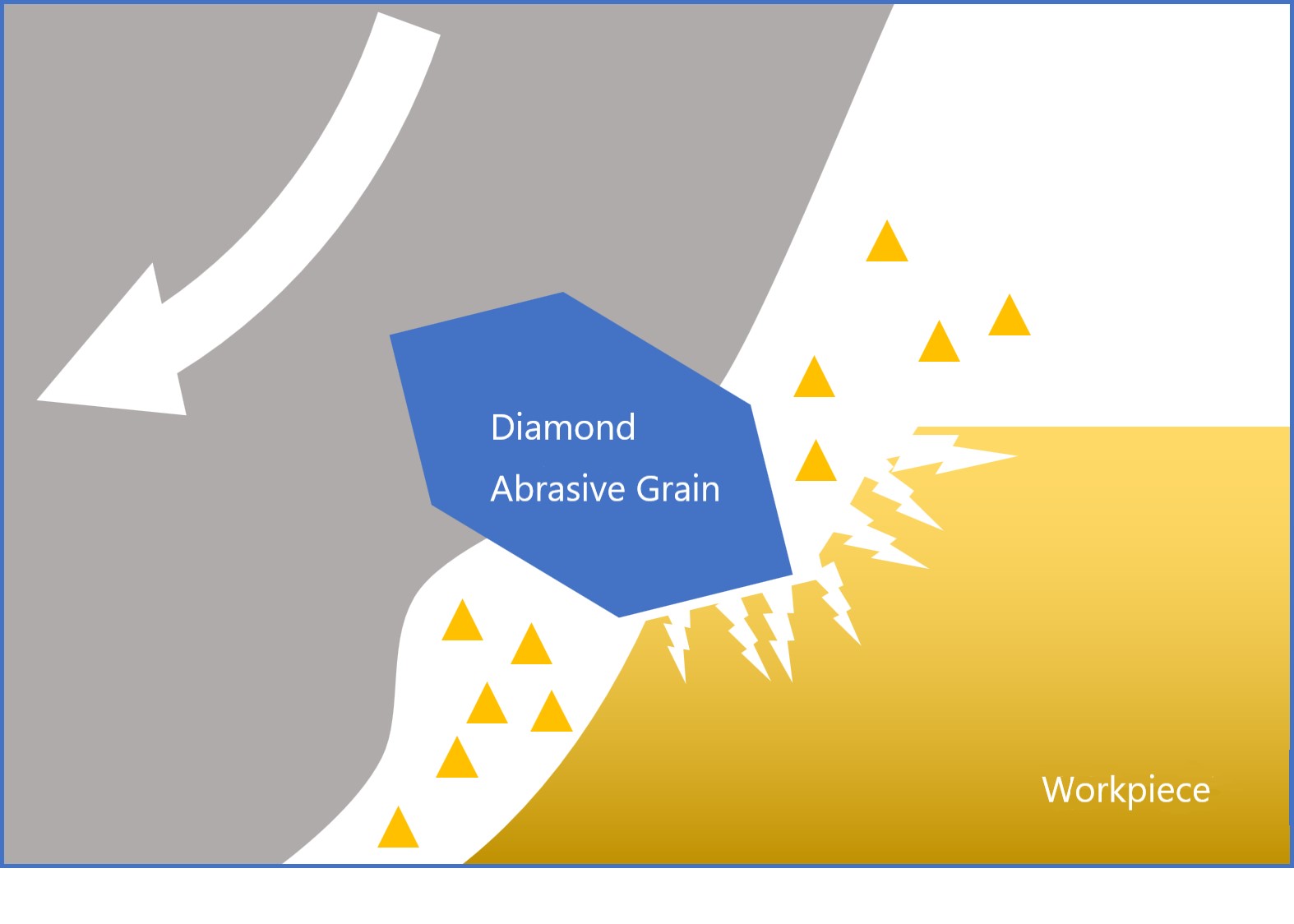

Dicing is the process of cutting silicon, ceramic, glass, resin substrates, etc. into chips (individual pieces) while spraying ultrapure water with a blade that rotates at high speed. In addition, the type of blade, blade rotation speed, cutting speed, etc. are adjusted to ensure cutting under conditions where cracking and chipping are less likely to occur.

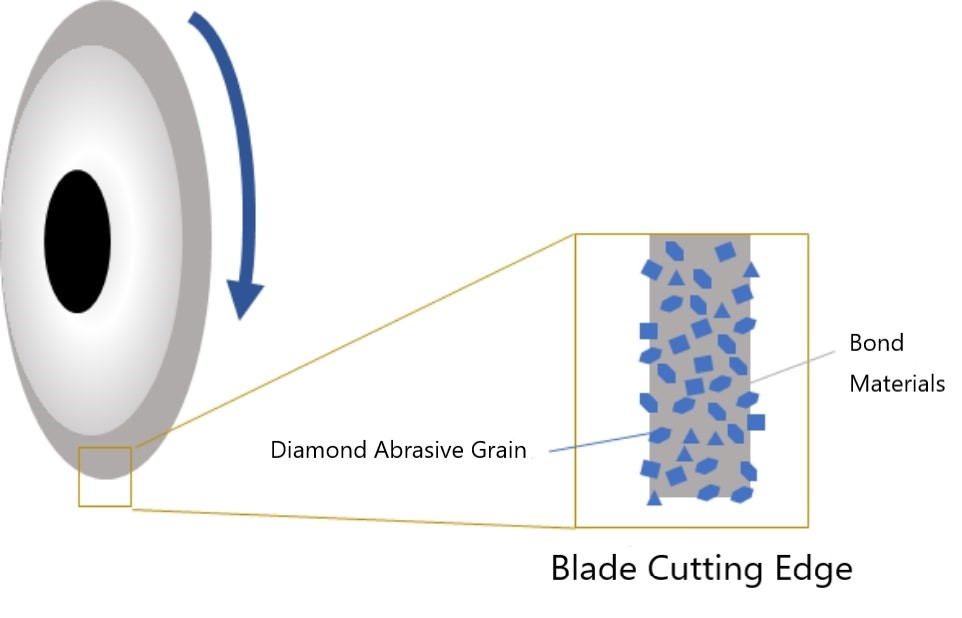

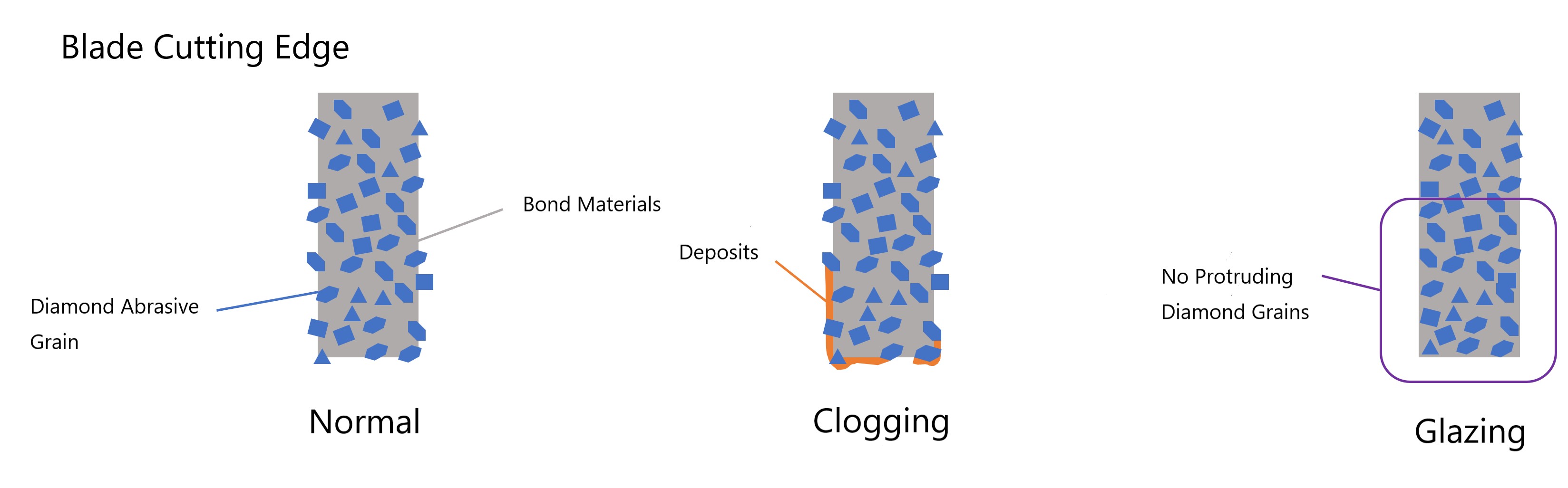

Blades

The dicing blade uses a diamond abrasive grain fixed with a bond.

There are various combinations of diamond grain size, bond material, etc.

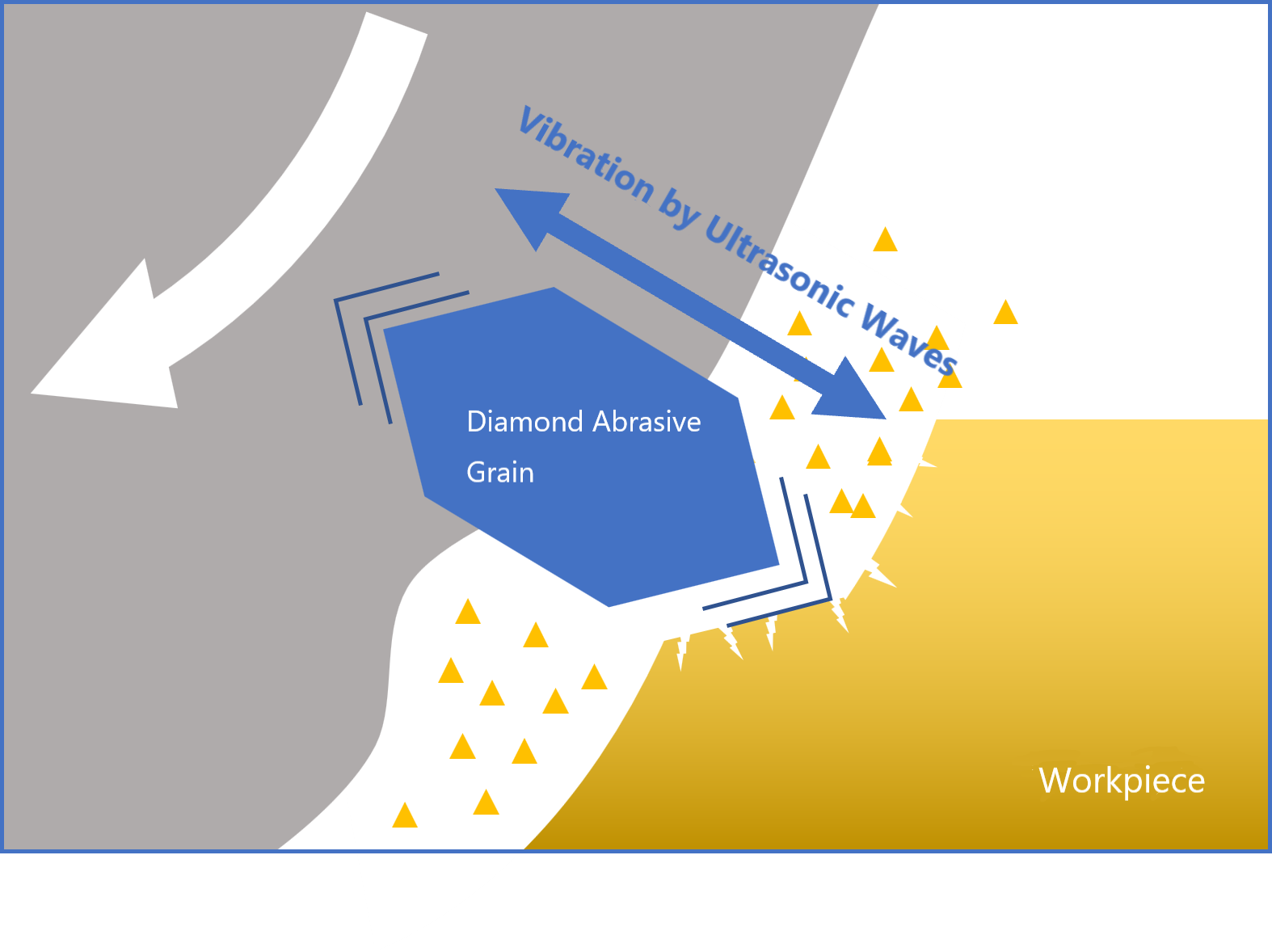

About Ultrasonic Wave Processing

Ultrasonic dicing can smoothly cut extremely hard and difficult-to-cut materials by applying ultrasonic waves to the blade.

Causes of Chipping in Dicing and Examples of Countermeasures

Chipping may occur when the material is cut by dicing.

There are many causes of chipping.

For example,

・There is a deposit on the blade (clogging)

・Diamond abrasive grains on the blade do not protrude (collapsed eyes)

・Material and blade diamond abrasive grain size do not match

In some cases, the cause can be determined by checking the state of chipping occurrence, the cutting edge of the blade, and know-how.

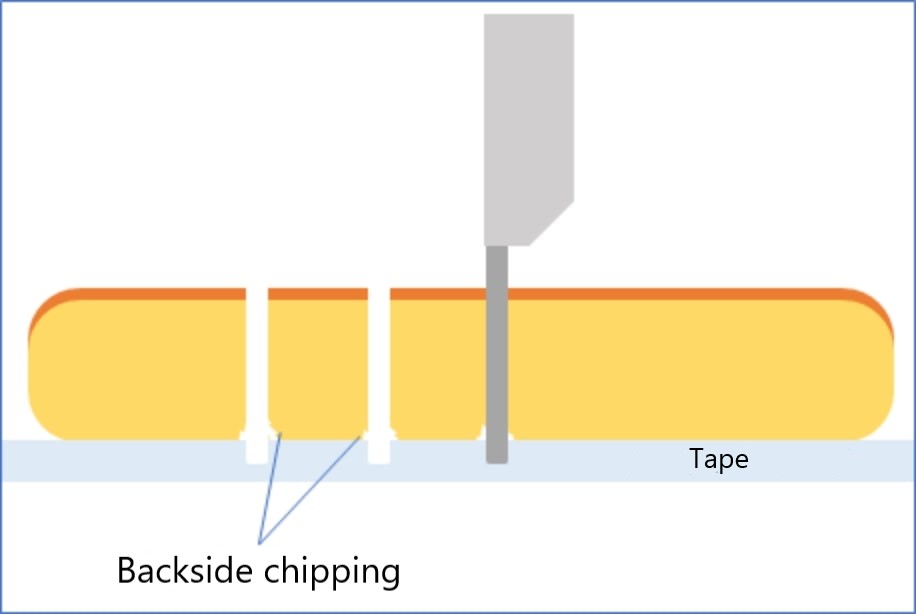

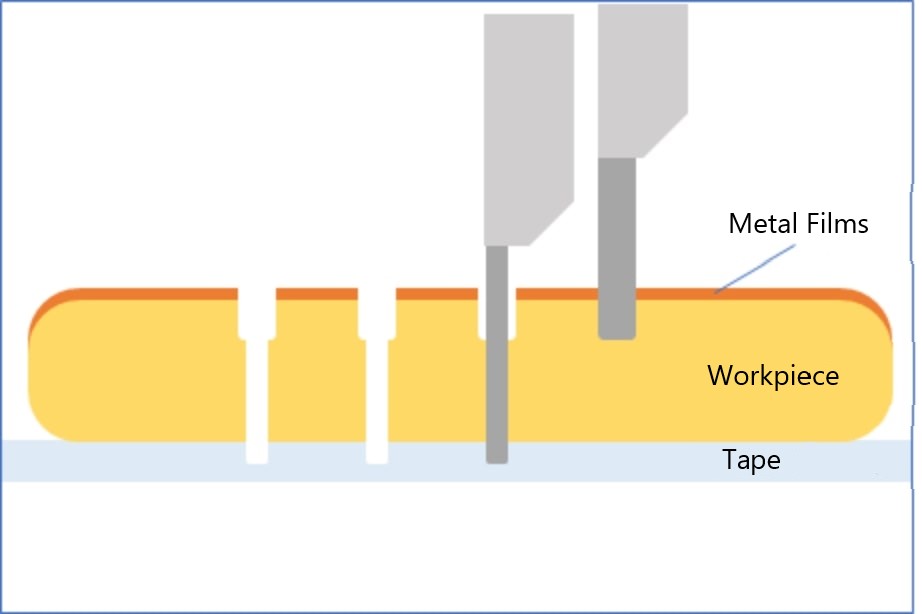

Countermeasure Example: Step cut

When a material is cut by dicing, chipping may occur not only on the front surface but also on the back surface.

Backside chipping is a phenomenon in which the backside is chipped due to clogging of the blade when cutting the metal film on the surface.

You can prevent this by using a two-step cutting method.

This method is called step cutting.

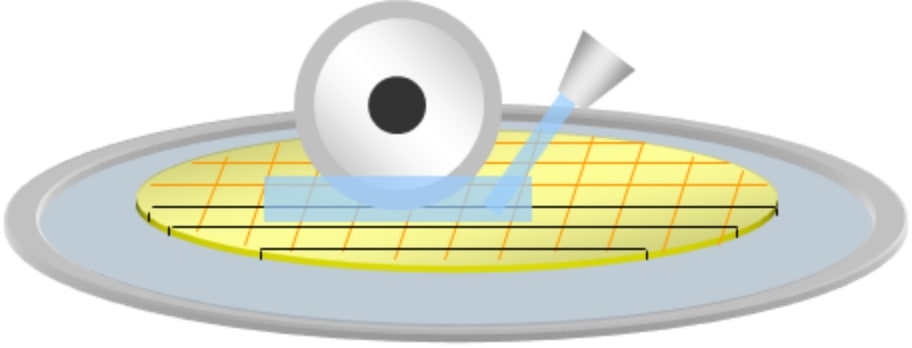

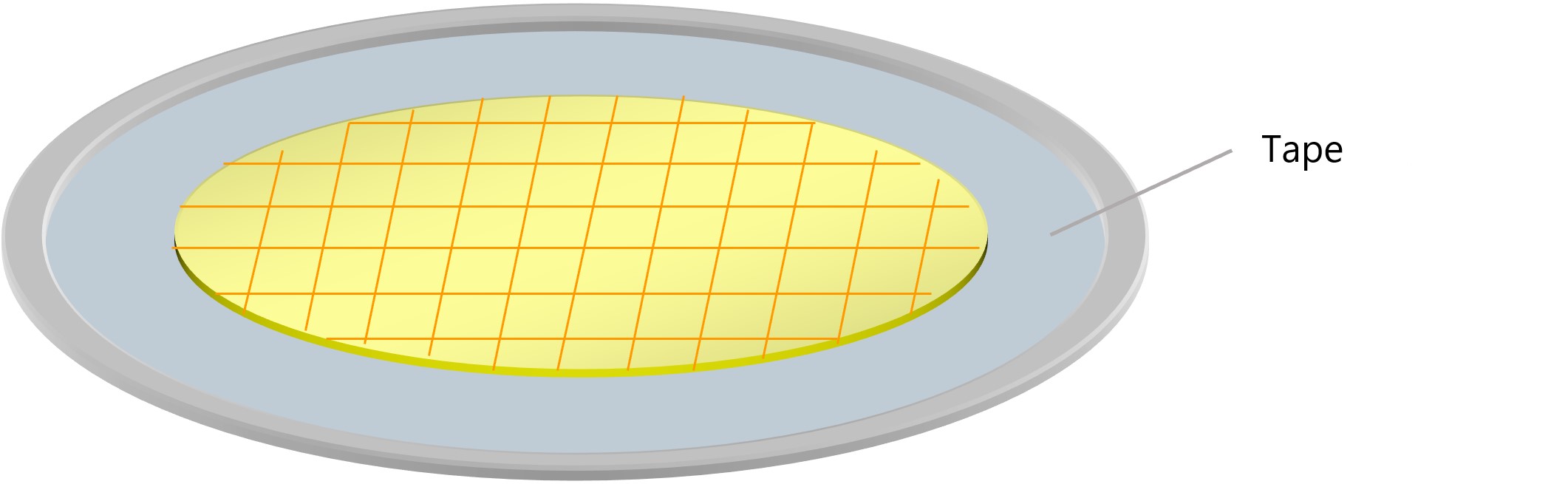

About Dicing tape

A sheet called dicing tape is affixed to the back surface of the wafer in advance so that the chips do not fall apart during dicing.

This tape is called “UV tape”. If ultraviolet light (UV light) is applied after dicing, the glue on the tape will harden and the chips will be easier to peel off.

There are dicing tapes suitable for the hardness and thickness of the glue for silicon, ceramic, glass, and resin substrates, so use them accordingly.

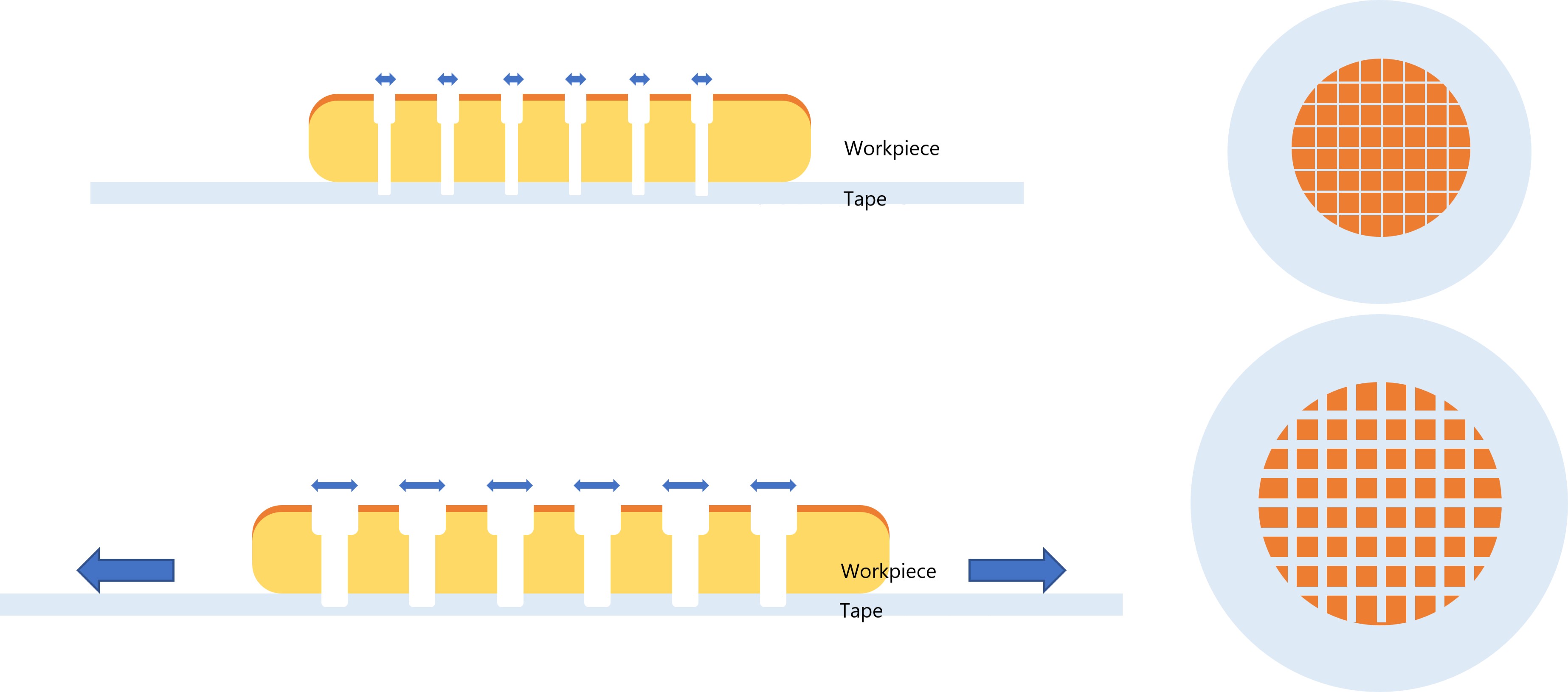

About Expansion

This is a process that stretches the dicing tape on chips cut by dicing to widen the gap between chips.

Widening the chip spacing reduces the risk of interference chipping during pickup.

Our process is accompanied by chip pick-up equipment.