Sorting IC Chips into Trays/ Visual Inspection

IC Chip Quality Is Controlled by Die Visual Inspection (Inspector/Machine) ,

and Consistent Support Is Provided for Sorting into Trays.

Miniaturization of IC chips is one factor in miniaturizing electronic devices.

In the same area, it is important to form high-density circuits, and fine processing of wafers is required. However, if a little damage or stress is applied to wafer processing after circuit formation, the defect rate may increase. Therefore, advanced processing technology and management system are required.

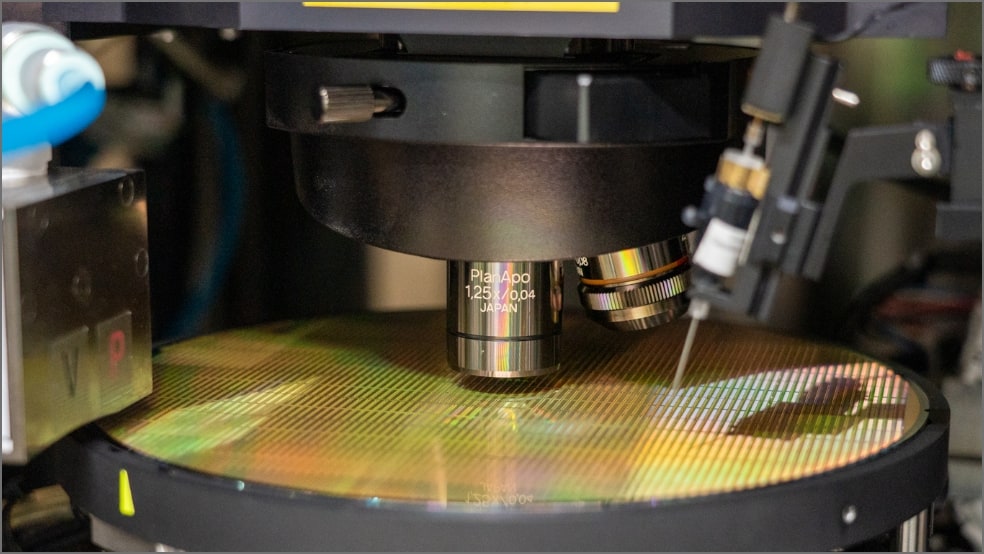

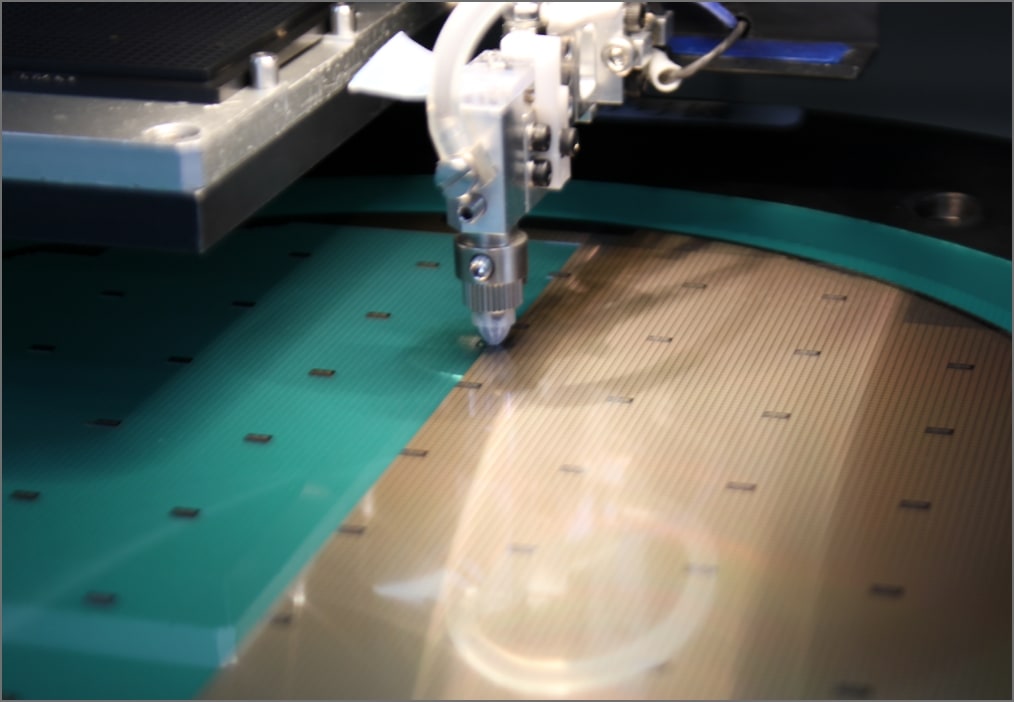

Wafer Visual Inspection by Machine

A unique algorithm detects defection on wafers with high throughput. Detected defective dice are recognized by the inking (bad mark), or the output into Prober data.

Die Visual inspection (Inspector/Machine)

Visual inspection is one of the important points in the process. We have set control points both visual inspection machine is superior in cost and qualified inspectors is superior in quality. In addition, we are able to achieve both cost benefits and quality assurance by combining these two methods depending on the product, tact time and quality.

Microscopic Visual Inspection by Qualified Inspectors.

Microscopic visual inspection is performed by qualified inspectors. We can inspect and ship various kinds of devices, with short lead time, based on the request of customers.

24 Hours Availability by Visual Inspection Machine

In addition to the inspection by the qualified inspectors, the inspection by In-Tray (Tray to Tray) Type Automatic Machine is available, for High-Volume Low-Variety production.

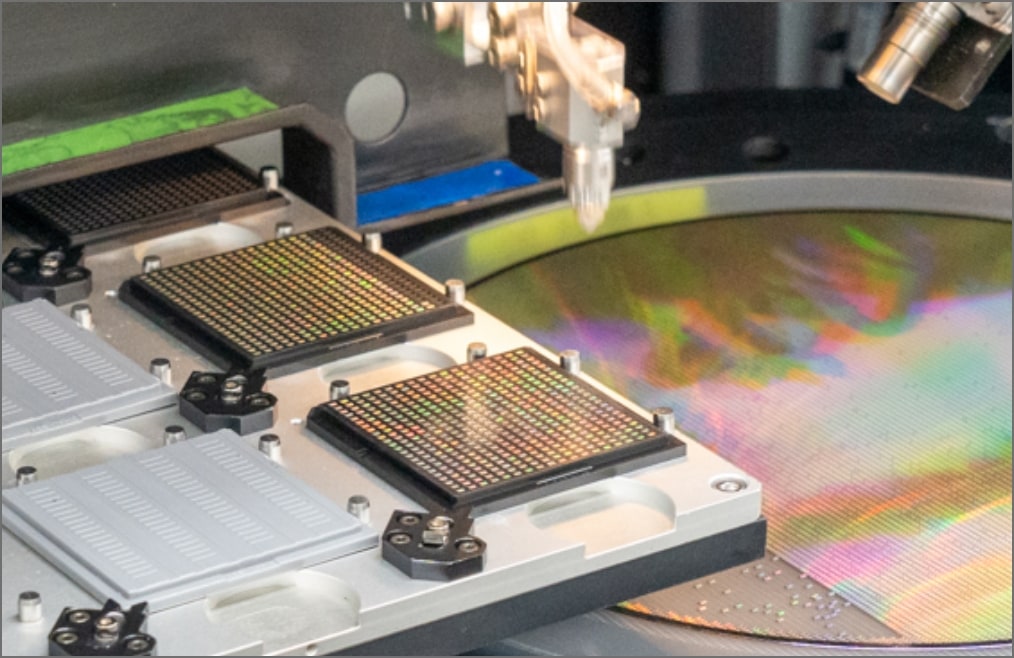

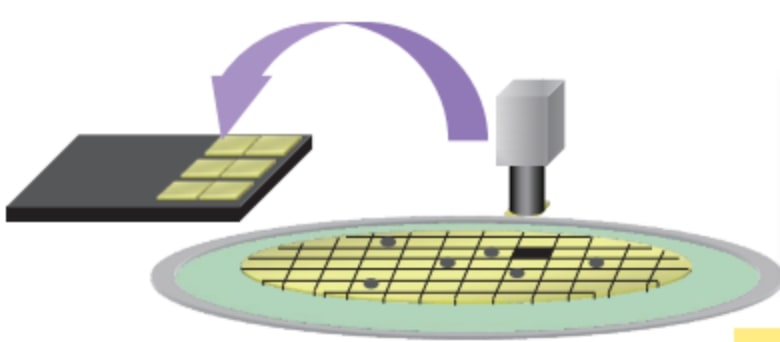

Sorting into Trays

Using special technology, we can pick up Minimal Dice with 0.5 X 0.5 mm, and Extremely Thin Dice with 0.25 X 9.8 mm. After the dicing, the dice are picked up with a collet, and put into the trays. As for the collet, we can use either die surface contact type or noncontact type, based on the request of customers flexibly

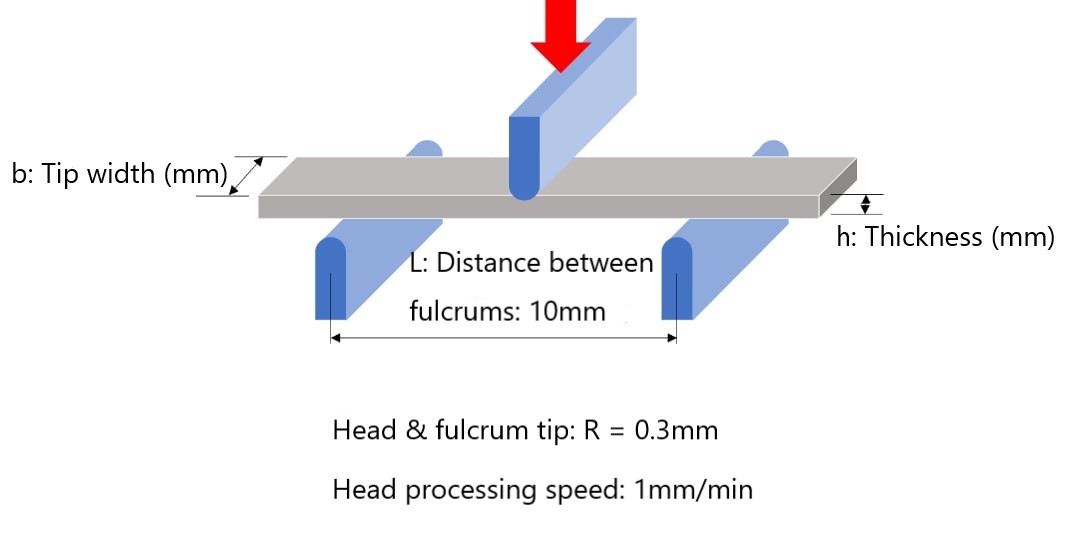

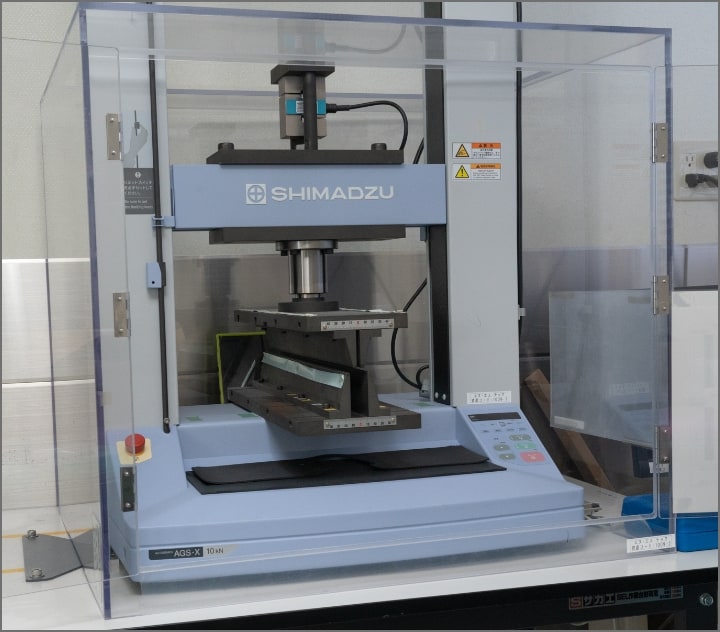

Bending Strength Measurement

We believe that regular measurements can stabilize the quality of wafer processing. Therefore, we have introduced a bending strength measuring instrument. And we are able to ensure stable quality and quickly launch prototypes.

In addition, we conduct grinding wheels evaluations with the theme of bending strength and make proposals that match each variety as part of R&D support.

Markless Sorting & Rank Sorting

The recognition of defective dice is possible, not only by marking but also by prober data etc. The latter is the so-called Mark-less Sorting. If the prober data have ranks, the dice can be sorted into different trays.

Compatible Chip Thickness: 50 μm or more

Compatible Tray Size: 2, 3, 4 inch

Tape to Tape

It is also possible to stick the chips on another tape.

Equipment

| Equipment | Manufacturer | Model | Number |

|---|---|---|---|

| Semi-Automatic Sorter | Daitron | WCS800 WCS700C WCS1200 |

8 2 1 |

| Semi-Automatic Sorter | Micro Engineering, Inc. | CT-200 | 2 |